Tank inspections don’t usually make it into “exciting news” territory. But if you’re in oil & gas, chemicals, water utilities, or really any industry that uses massive storage tanks, you know this stuff matters. A small crack or unnoticed corrosion spot can turn into a nightmare: leaks, shutdowns, fines, or worse, accidents.

Traditionally, tank inspection services meant a lot of heavy lifting—literally. You had to drain the tank, send people inside (confined space entry is no joke), or rely on older methods like radiography. It worked, but it wasn’t always safe, fast, or super accurate.

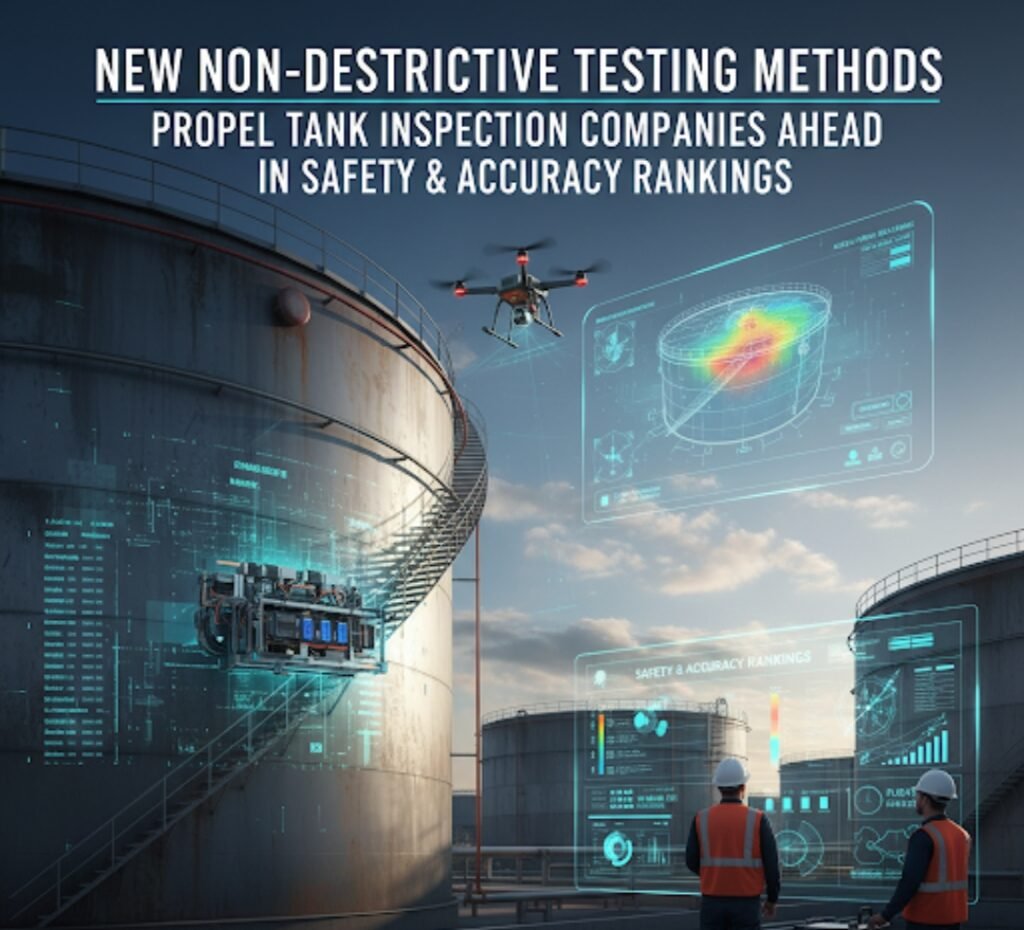

That’s where non-destructive testing (NDT) methods are totally changing the game. Companies using these advanced techniques are leapfrogging others in safety and accuracy rankings. It’s kind of wild to see an old-school, gritty industry get such a tech glow-up.

So, What Exactly is NDT?

If you’re not familiar, non-destructive testing is basically what it sounds like: testing without breaking, drilling, or damaging the asset. Instead of cutting into a tank wall or shutting everything down, inspectors use advanced tools—think ultrasonic testing, magnetic particle inspection, eddy current, and even acoustic emission methods.

Translation: you get the inside scoop on what’s happening with the steel, welds, and coatings without compromising the tank. Pretty neat, right?

Why Safety Matters So Much Here

Confined spaces and scaffolding setups are some of the riskiest parts of traditional tank inspections. People literally had to climb inside with flashlights and harnesses. It’s slow, and every second someone spends in there is another chance for something to go wrong.

With NDT, a lot of that risk is minimized. Ultrasonic testing, for example, can check the thickness of tank walls from the outside. You’re keeping inspectors out of dangerous situations while still getting reliable data. That’s a win-win in my book.

The Accuracy Jump

Here’s the other kicker: accuracy. Visual tank integrity inspection services are limited—you can’t see beneath the surface. Radiography was decent, but slow and costly. NDT methods, especially when paired with digital data collection, pick up microscopic cracks, early corrosion, and even stress points that would’ve gone unnoticed.

In other words, companies are catching problems way earlier. And when you catch issues early, you save money, prevent downtime, and avoid disasters. That’s how some inspection companies are ranking higher than others right now—they’re proving their inspections are more reliable.

Where Drones & Robots Fit In

And yeah, I can’t talk about the “future” without mentioning drones and robots. When you mix NDT tools with robotic crawlers or drones, it’s a whole new level. Imagine a robot crawling along a tank wall, running ultrasonic tests as it goes, or a drone doing magnetic particle scans from above.

It sounds futuristic, but it’s already happening. That combo of robotics + NDT is why some inspection companies are pulling ahead in safety and compliance ratings.

The Real-World Payoff

This isn’t just a “cool tech” thing. The payoff is massive:

- Fewer shutdowns → companies save millions.

- Better compliance → regulators love it.

- Safer workers → no one’s climbing into a tank unless it’s 100% necessary.

- Happier clients → because accuracy means fewer surprises.

It’s not flashy like self-driving cars or AI art, but in industries where safety and reliability are everything, this is revolutionary.

FAQs

Q: Does this mean humans won’t be needed for inspections anymore?

Nope. Humans still play a huge role in analyzing the data and making judgment calls. The tech is a tool, not a replacement.

Q: Is NDT more expensive than traditional inspection methods?

Upfront, it can be. The equipment isn’t cheap. But when you factor in reduced downtime, fewer accidents, and longer tank life, it usually pays for itself.

Q: Can NDT methods detect all problems?

Not every single one. Each method has its strengths. That’s why inspectors often use a combo of different techniques to cover all bases.

Q: Are drones and robots really reliable for this kind of work?

They’re getting better every year. Right now, they’re great for reducing human risk and speeding things up, but there’s still a lot of fine-tuning happening.

Tank inspection companies that are adopting non-destructive testing (NDT) methods are blowing past old-school competitors in safety and accuracy. Fewer people in risky situations, earlier problem detection, and way better efficiency. Add in drones and robots, and you’ve got the future of inspections staring you right in the face.

Experienced SEO Specialist and Web Developer with a strong focus on off-page SEO and guest posting. With 3 years of proven expertise, I help businesses improve their search rankings and build sustainable online presence.